There are many boaties who tow their boats on a trailer, finding the best spots around the city, or in other states, to launch. So maintaining trailers should not be taken for granted. Trailer boat expert, Marcus Gardner of Swiftco Trailers, shares important information about boat trailers.

In many ways, the trailer plays a more vital role than the boat itself. Imagine not having a functioning trailer; you obviously will not be able to transport your boat to the water. And more importantly, a faulty trailer during transport can endanger you and your family, and the others around you. So, trailer maintenance and regular inspection are imperative.

Buying a replacement

When purchasing a replacement trailer, ensure you have the boat adjusted to your trailer. Replacement trailers are universally suitable and as such can be custom fit to accommodate your boat. The following are important things to check before driving off with the replacement trailer.

Keel Rollers and Wobble Rollers. The two main adjustments are the keel rollers and the wobble rollers. The keel rollers are adjustable in the vertical plane (up and down) to suit the keel shape of your boat. The strongest part of the boat is the keel and the keel rollers are designed to take 85 to 90 percent of the boat weight. The wobble rollers have two adjustments. They can move vertically and horizontally. Wobble rollers serve two purposes: to keep the boat stable and sitting upright on the trailer, and to guide your boat on and off the trailer.

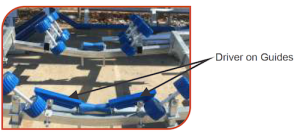

Optional guides. In addition, an optional “Driver on Guides” can be fitted. These are set either side of the keel roller to align the boat back to the centre keel roller in the event you bring the boat in on an angle.

Tying the boat down. Once the boat is fitted to the trailer correctly, the final task before taking it on the road is to tie the boat down. There is a tie point at the front of the trailer at the base of the winch post. This is to tie the front of the boat to the trailer. The other tie points are either on the side or at the rear of the trailer.

You will require a long ratchet strap. The strap goes over the rear of the boat from one side to the other. Tighten the strap to anchor the rear of the boat. There is a safety chain under the winch. This needs to be attached to the front of the boat. It should be noted that the winch is only there to retrieve the boat, not to anchor the boat to the trailer. Finally, check tyre pressure and inflate to the correct pressure, usually around 45 to 55 PSI, depending on the weight of the boat-trailer combination.

Initial trailer checks after first 10km with boat on trailer

Below are items that require checking and adjusting as required in the first 10 to 100 kilometres of using the trailer.

- Check and adjust the wheel bearings and repack through the bearing buddie grease nipple.

- Check and adjust brake cable, as this can stretch during this period.

- Grease the grease nipple on the two-tonne tow hitch.

- Check tyre pressure and inflate as required.

Washing the trailer

Preserving galvanized zinc coating. The environment in which the trailer is used, stored and maintained determines the level of deterioration of the galvanised zinc coating. Locations with high salt content and high humidity commonly cause the galvanised finish to deteriorate very quickly; hence, a higher degree of care is required to slow the deterioration of the zinc. Tip: Use soapy water with brush as this will take any salt residue off the galvanizing, thus extending the life of the trailer. Always wash out brake callipers with soapy water after each use. This will increase the life of the brake pads and callipers.

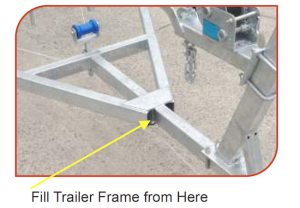

Keeping drain holes clear. It is important that the drain holes throughout the trailer frame are kept clear and checked as a regular maintenance schedule. This allows for trapped water in the frame to clear. Tip: Using a sponge or rag, block the end of the main frame. Then, using a hose insert at the front of the main frame, flush with clean tap water. Run water for around 5 minutes. This will flood the complete chassis including the cross members as they are all open to each other. The water will run out of all the drain holes in the cross members, cleaning out all saltwater and residue. Failure to carry out the above cleaning process will greatly reduce the life expectancy of your trailer.

The importance of bearing buddies

Bearing buddies are fitted to all reputable boat trailers. These are designed to keep water out of the bearing hub when you drive the trailer into water when launching or retrieving your boat. The ideal time that you should grease the bearing buddies is prior to putting the trailer in the water. If not, at the boat ramp, you will have a situation where you have a hot hub with liquid grease in the hub. Taking the trailer with a hot hub into cold water will allow a small amount of water to seep in through the rear seal of the hub, causing damage to the bearings when driving down the road. Therefore, pumping grease into the hot hub prior to entering the water will cool down the hub, and pack the hub with solid grease, eliminating any possibility of water entering the hub.

The wheel bearings

Check wheel bearings and brake adjustment within the first 10 to 50 kilometres of using the trailer. Follow the system on bearing-buddies checking. Servicing wheel bearings should be done every six months for regularly used boat trailers.

If the wheel does not rotate on the axle smoothly, then you will need to replace the

bearings. This should be carried out by an authorised mechanic. It is good practice to get the trailer checked by a mechanic every six months to avoid expensive on-road costs.

Handy tips

Coupling – This needs to be greased every six months or when there is no grease present on the shaft. All the bolts and nuts need to be checked for tightness.

Axles and Springs – It is recommended that you inspect the suspension components at least twice a year for loose u-bolts, bolts and breakage of the leaf springs. Spraying the axle, hubs and springs with anti-moisture anti-corrosion lubricants after washing the trailer is recommended.

Brakes – These need to be serviced every six months. Brake adjustment for the mechanical over-ride system can be adjusted at the front pulley or the adjustment bolt on the calipers. Remember to leave enough slack in the cable to allow for the flex in the trailer while under tow.

Jockey Wheels – Ensure that when the swing-up jockey wheel is swivelled from the horizontal position to vertical, the spring-loaded handle and extension pins lock securely into both holes in the jockey wheel mounting plate. Lubricate regularly to keep rust away.

Trailer lights – Every six months, check for cracked wiring and damaged lenses. Ensure that all functions of the lamps are working.

Tyres – Regularly check for the correct inflation pressure. Uneven tyre-wear inspection should be carried out. Tyre rotation should be carried out every six or twelve months depending on trailer use.

Hand winch – Do not overload your winch. Use it only for the application it has been supplied for on normal ramp conditions. Winches are supplied with a webbing strap which has a higher load rating and braking strain. Ensure that the winch strap is dry. If the winch strap is wet, unwind the strap and allow it to dry out. This will avoid rust on the drum and the strap from deteriorating. Oil the winch shafts, bushes and gears as needed.

Editorial by Andy Kancachian